Services

Retail / Commercial Printing

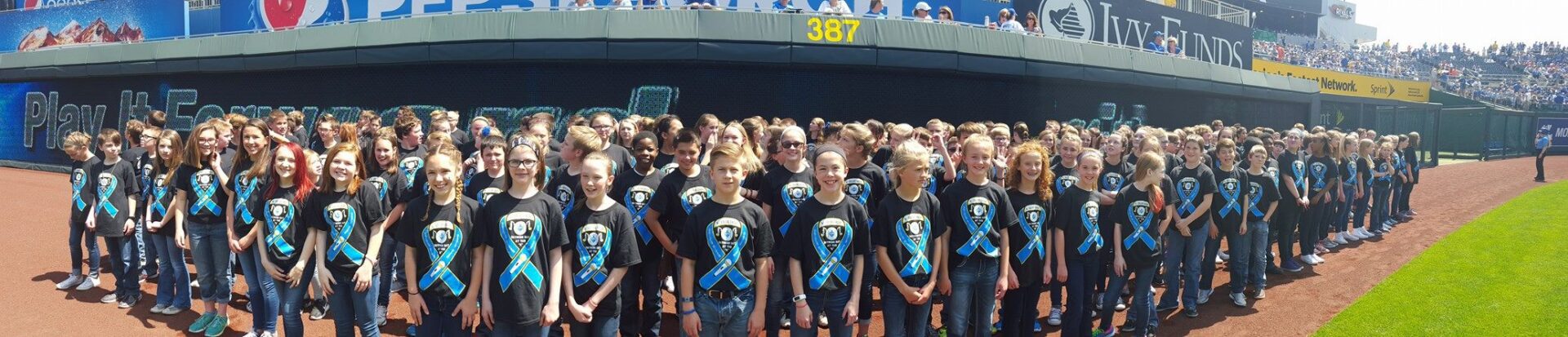

In retail screen printing, we work directly with the end customer to fulfill their goals. The products printed may be shipped or picked up by the customer. We work directly with the customer about their needs, provide artwork, help you select and provide garments, and then print and fulfill the job. We work with you to provide end-to-end service.

Contract Screen Printing and Embroidery

Contract printing or embroidery is an agreement between two companies to subcontract embellishment on provided items. In contract screen printing, our brand is not shown to the end customer. The products printed are often drop shipped to and from on the clients account. The Client will provide garments, artwork, and all necessary details to complete the job. To receive a copy of our contract pricing list please send us an email with a request for contract pricing. You will be required to provide your state Sales and Use Tax Exemption Certificate (MO 149) and a copy of your state issued retail sales license.

New to Screen Printing?

To us printing is fun and exciting. Its art and art should be shared. Please visit our page New to Screen Printing for a step by step introduction to the process.

Graphic and Art Solutions

Looking for a new logo? Or maybe your next band t-shirt or marathon needs a new design? Our art department will go through your many options to find a solution that works best for you or your companies needs.

Why You Should Make Mmsp Your Go-to Printer

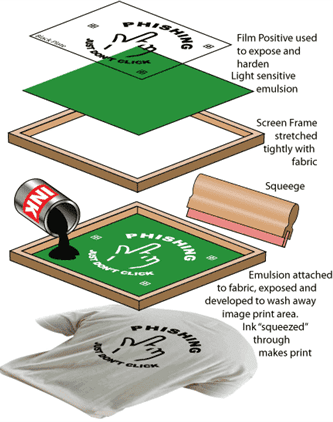

The Screen Printing Process

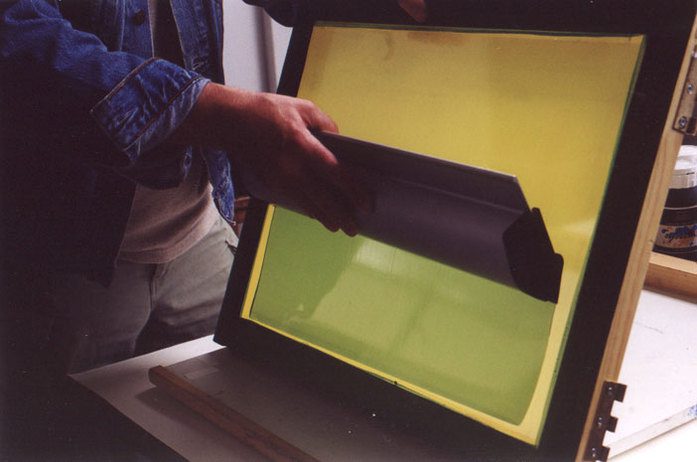

The screen printing process or silk screen printing is a printing technique particularly suited for flat or relatively flat surfaces. The heart of the process involves a fine mesh or screen that is tightly stretched around a rigid frame. The areas that are not to be printed are masked out on the screen, and to create the print, the framed screen is positioned over the item to be printed, along with a dollop of thick ink. A squeegee is then used to press the ink through the screen.

The masked areas prevent ink from passing through, but the unmasked areas allow the ink to be imprinted on the material. The item is then sent on a conveyor belt through a heat-tunnel. This curing process ensures that the inks dry quickly so that they materials can be stacked or packaged. Properly cured inks will remain on the printed substrate even under harsh conditions.

If more colors are desired in the final design, the process is repeated with different screens. A design that requires four different colors would, therefore, require four different screens. The screens are usually placed on a rotary press that allows the different color prints to be properly aligned or registered with each other. Some screen-printers have fully automatic presses that do not require any manual labor other than set-up and loading/unloading.